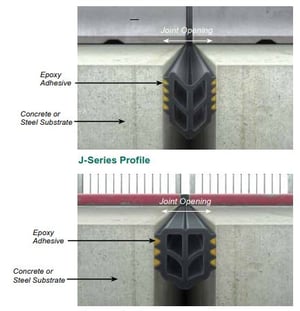

J & JP Series Sealing Systems include an extruded elastomeric profile and high-strength, two-part epoxy based structural adhesive. Product when inserted into an expansion joint in a substrate, will seal the opening from intrusion of water and debris.

The working life of the J-Seal epoxy after being mixed is approximately 10 minutes. If spread 1/8" to 1/4" thick on cardboard or laminate, 30+ minutes. The epoxy generates its own heat and when left in the can or spread too thick (just poured out on cardboard) it diminishes your working time drastically.

Product Preparation

- Product Installation Details - Premix DSB High Strength Epoxy Parts A and B individually if

not using entire container.

not using entire container. - Proportion equal parts by volume of Part A and Part B into a clean mixing container.

- When measuring, Do not use one tapered container such as a Dixie paper cup, filling it half full of A and half full of B; the correct ratio (1:1) cannot be achieved due to tapered feature of container.

- Thoroughly mix using low speed drill (400 to 600 RPM) and paddle mixer for 3 minutes, scraping sides of container until a uniform gray color is achieved.

- Only mix amount of epoxy that can be used within its gel time. Spread mixed epoxy out thin on a hawk to extend gel time. If you pile it up, the gel time will be shortened due to the greater mass and exotherm.

Installation Detail

J & JP-Series Sealing Systems Ease of Installation – J & JP Seals have specially designed internal webbing to facilitate installation and do not require the use of a vacuum to collapse or inflate the seal for purpose of installation.

- Concrete and Steel Adhesive is VOC Compliant – The adhesive has a zero VOC rating. The material resists humidity, salt spray and extreme temperature ranges.

- Fatigue Tested for One Million Cycles – The profiles were cyclically opened and closed in tension and compression for one million cycles. The seals were stretched to 200% of their original width with no bond failure.

No Blockout Recess Required – The J & JP-Series are a solid choice with the precast concrete industry in that no blockout recess is required. The seal profile can be installed directly between the joint interfaces.

Safety Data Sheets

Safety Date Sheets for D.S. Brown High Strength Epoxy – Part A, D.S. Brown High Strength Epoxy – Part B, and J&JP Seal Conditioner.

New Jersey Turnpike Project

J & JP Series Sealing Systems, one of D.S. Brown’s key proprietary product lines, were provided for an ambitious project to widen the New Jersey Turnpike, one of the most frequently traveled highways in the United States.