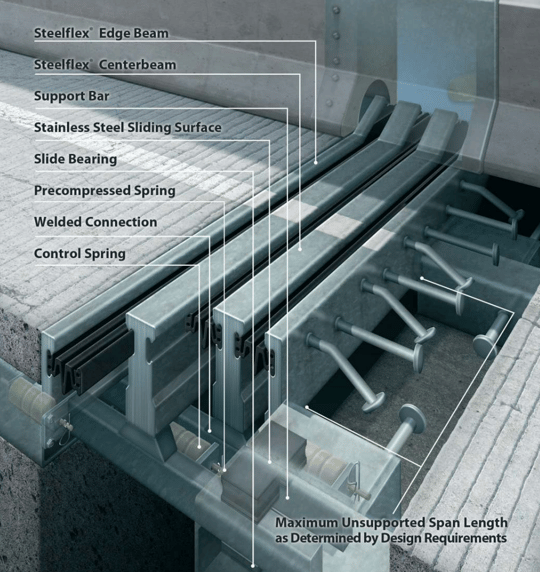

D.S. Brown Steelflex® Modular Expansion Joint Systems have gained overwhelming worldwide acceptance for accommodating and sealing large joint movements on bridge structures.

Answer: Many factors can influence box spacing. Generally, for our standard modular joint systems, when AASHTO LRFD Bridge Design Specification 8th Edition, 2017 (or later) is specified, our maximum box spacing may be up to 4'-0". (The prior editions of AASHTO allowed slightly greater spacing).

Other governing specifications, loadings, and bridge requirements (such as girder locations) may greatly affect the box spacing and locations. In all cases, please keep in mind that as a standard, we incorporate box spacings in increments of 3". We try to reduce the box spacing on either side of a field splice. We also try to reduce the box spacing at the outside boxes while trying to maintain a maximum cantilever of 18" from the furthest support bar to the gutter line. Bridge design details that allow for such placement include unobstructed block outs, constant depth block outs, and block outs that extend the full width of the bridge deck.

Learn more about Expansion Joint Systems

Since the early 1960s The D.S. Brown Company has provided expansion joint systems and structural bearing assemblies for bridges around the globe. Bridge expansion joint systems are directly exposed to vehicular wheel loads and, therefore, must resist dynamic forces causing fatigue and wear. In addition, these expansion joint systems must remain watertight to protect the bridge superstructure and substructure from corrosion.