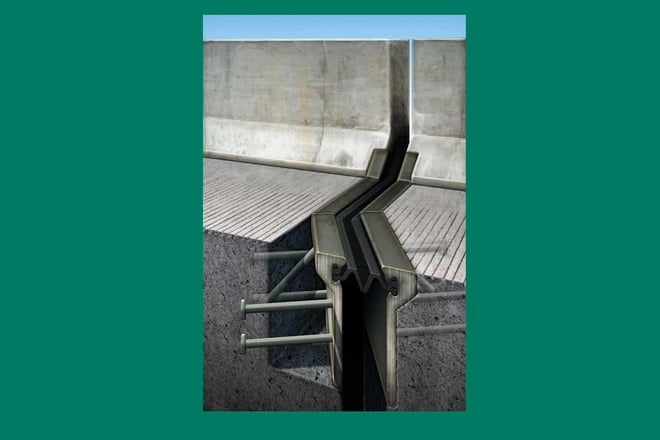

How do you support strip seal frame rails for installation?

Steelflex® Strip Seal Expansion Joint Systems provide superior watertight performance and longevity over bolt-down, segmental bonded and pourable expansion joint systems.

Answer: Common methods of temporarily supporting strip seal frame rail for installation include:

- With a block-out in the bridge deck and the frame rails are suspended from above (hanging).

- With a monolithic deck pour the frame rails are either tied to the deck reinforcement steel and formwork or the frame rails are attached with joint supports connected to the superstructure. Joint supports typically increases product lead time and cost.

Joints are recommended to be placed as a secondary pour (block-out method either way), to eliminate any undo rotational movement caused by lengthy monolithic casting. Using block outs typically assures a better, more consistent result over the monolithic deck pour method.

Learn more about Expansion Joint Systems

Since the early 1960s The D.S. Brown Company has provided expansion joint systems and structural bearing assemblies for bridges around the globe. Bridge expansion joint systems are directly exposed to vehicular wheel loads and, therefore, must resist dynamic forces causing fatigue and wear. In addition, these expansion joint systems must remain watertight to protect the bridge superstructure and substructure from corrosion.